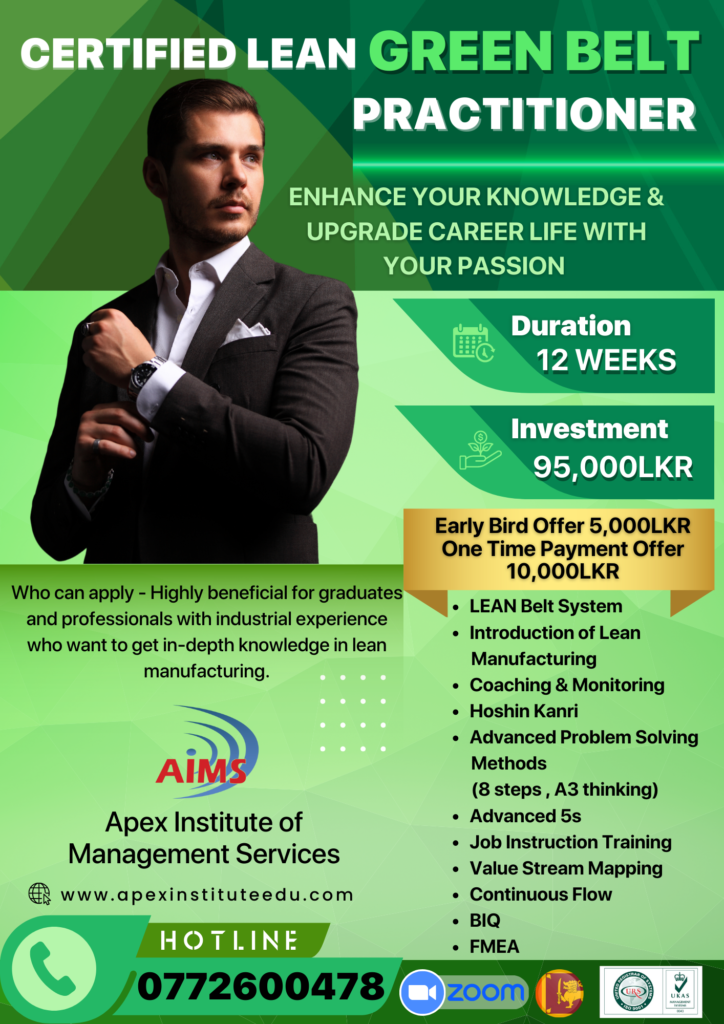

Lean Green Belt is a level of certification within the Lean methodology. It is the second level of training after Lean Yellow Belt and before Lean Black Belt.

The Lean Green Belt certification is designed to provide individuals with a deeper understanding of the Lean methodology, including the PDCA, process, statistical tools, and process improvement techniques. Green Belt practitioners are trained to apply these concepts to their work and lead smaller process improvement projects within their organizations.

Here are some key responsibilities and benefits of a Lean Six Sigma Green Belt certification:

- Leading Smaller Improvement Projects: A Lean Green Belt practitioner is responsible for leading and managing smaller process improvement projects. They are trained to identify the root cause of problems, develop and implement solutions, and sustain the improvements over time.

- Participating in Improvement Teams: A Lean Green Belt practitioner is often a member of cross-functional improvement teams. They work collaboratively with other team members to identify improvement opportunities, develop solutions, and implement changes.

- Applying Statistical Tools: A Lean Green Belt practitioner is trained to use statistical tools and data analysis to identify trends, patterns, and opportunities for improvement.

- Continuous Improvement: A Lean Green Belt practitioner is responsible for driving continuous improvement within their area of the organization. They are trained to identify opportunities for improvement, prioritize improvement projects, and implement changes that lead to increased efficiency and effectiveness.

- Career Advancement: Obtaining a Lean Green Belt certification can enhance career prospects for practitioners. It demonstrates proficiency in Lean methodologies and can lead to career advancement opportunities, including promotions, salary increases, and higher job prospects.

In summary, Lean Green Belt certification provides individuals with a deeper understanding of the Lean methodology, allowing them to lead smaller process improvement projects, participate in cross-functional improvement teams, apply statistical tools, drive continuous improvement, and enhance their career prospects.

-

0 % In Progress